Bayer AG

Engineering & Technology

Environmental & Solids Processing

Building E 41, 324

51368 Leverkusen

Deutschland

Tel.:+49 (0)214 30 70387

yannick.feith@bayer.com

www.bayer.com

Ansprechpartner: Herr Yannick Feith

Berghof Membrane Technology GmbH

Arbachtalstr. 26

72800 Eningen

Deutschland

Tel: +49 (0)7121 894 244

Fax: +49 (0)7121 894 100

info@berghofmembranes.com

www.berghofmembranes.com

Ansprechpartner: Dr.-Ing. Kimball Roelofs

ABOUT US

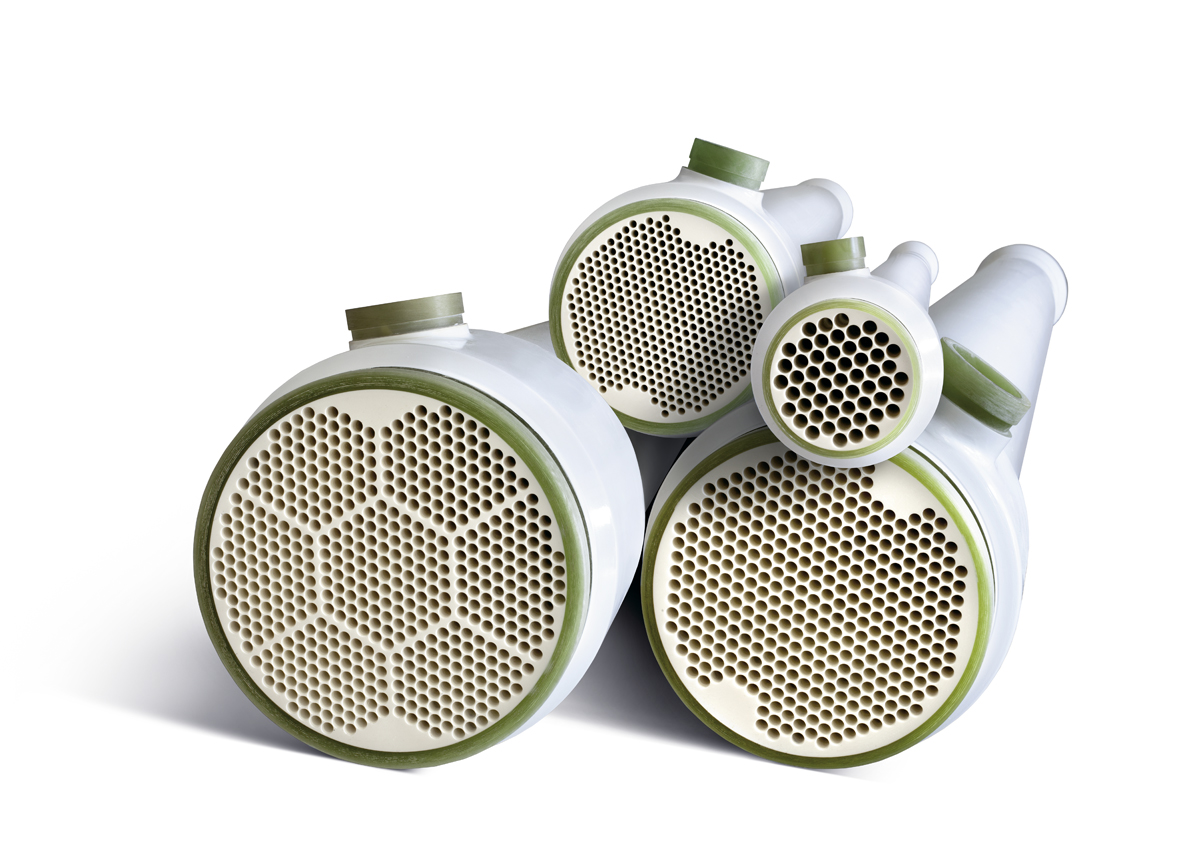

Berghof Membrane Technology GmbH (Berghof Membranes), part of the Berghof Group, is the leading manufacturer of tubular membranes for the filtration and separation of process streams and wastewater in a variety of industries including dairy, landfills, mining, food & beverage, chemical & pharmaceutical, and oil & gas.

With 50 years of experience and over 2,000 installed systems across the globe, Berghof Membranes prides itself on the robustness, flexibility energy efficiency, and superior quality of its external filtration membranes and solutions.

We focus on what we do best: to develop, manufacture and deliver premium quality tubular membrane products designed to help industries achieve sustainable growth and minimize their environmental impact. Over the years, we have achieved rapid growth and success because we remain true to our core values and our core technology. Berghof Membranes products are manufactured to the highest quality standards in the company’s fully automated LEAN production facility in Eningen, Germany. We pride ourselves on the premium quality, reliability, and efficiency of our manufacturing. So, when it comes to membrane filtration, think outside the box and contact Berghof Membranes today.

Blue Foot Membranes GmbH

Benzstr. 5

48369 Saerbeck

Deutschland

Tel: +49 (0)2574 8875 8200

Fax: +49 (0)2574 8875 8201

srichter@bluefootmembranes.com

www.bluefootmembranes.com

Ansprechpartner: Herr Steffen Richter

ABOUT US

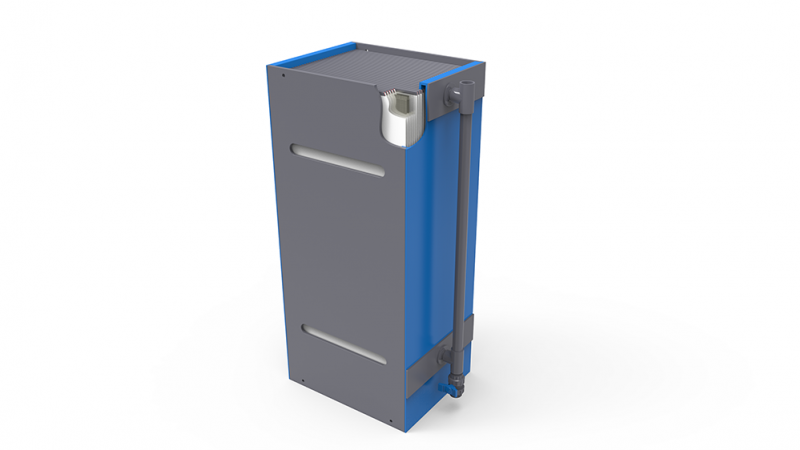

Blue Foot Membranes (BFM) is producing and commercializing the unique and worldwide-patented Integrated Permeate Channel (IPC™) technology.

IPC™ membranes - the world’s first fully back washable flat sheet membrane

Installed in existing as well as in new membrane bioreactor, IPC™ membranes can double the output capacity per square meter and lower the aeration cost by at least 50% of your exisiting or future MBR.

IPC™ Technology

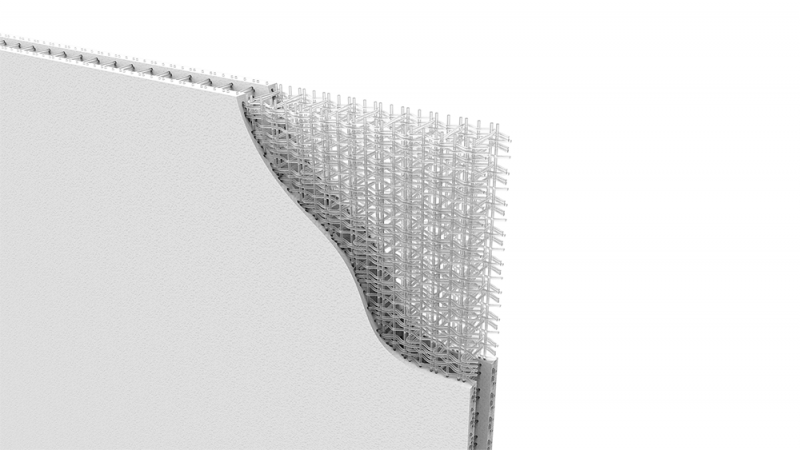

Back in 2005, the first conceptual idea of Integrated Permeate Channel (IPC™) membranes was launched at VITO, a leading European independent research and technology organization in the areas of cleantech and sustainable development. Now, a decade later, the advantages of the patented IPC™ technology have been clearly demonstrated in the field.

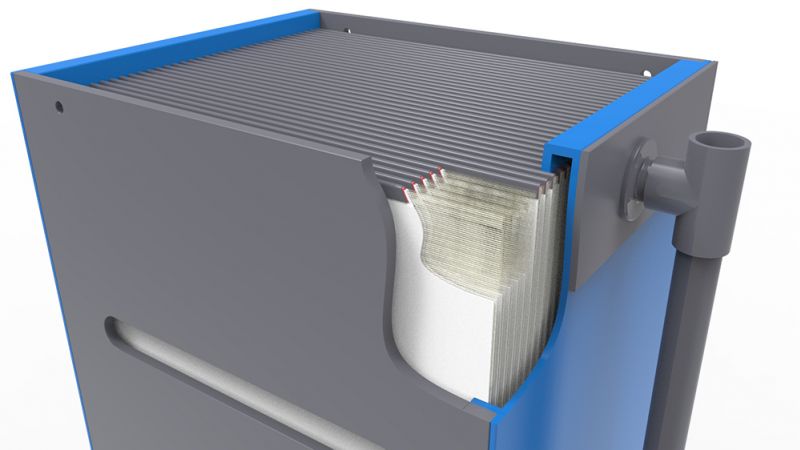

The IPC™ membrane comprises a permeate channel, consisting of an open 3D spacer fabric. The membrane layers are coated directly on the 3D spacer fabric. As such, a membrane envelop is formed whereby the membrane layers are mechanically anchored in the fabric surface allowing for rigorous backwashing, up to 2 bar(g) of the membrane. The membranes’ thickness of only 3mm makes a 50% higher packing density possible when compared to other commercial available flat sheet membranes.

BFM product

IPC™ membranes are the world’s first thoroughly back washable flat sheet membranes. Thanks to the capability of high pressure back washing, improved fouling control of the membranes can be achieved. This improved fouling control results in flux improvement of more than 100% compared to commercial available flat sheet membranes.

With a total thickness of 3 mm per membrane, a 50% higher packing density is achieved. In combination with the triple deck module configuration, the first result is a substantial lower footprint of your installation.

Secondly, since only one aeration system per triple deck module configuration is needed, the aeration demands is significantly lower compared to other modules, which reduces the operational cost substantially.

Efficient physical cleaning is crucial for the lifetime of the overall filtration system. The flat sheet design enables a well-defined flow pattern and allows for more than 600.000 ppm hours of Chlorine. The IPC™ membrane is less prone to braiding and clogging compared to hollow fiber modules. Furthermore the membrane layers are mechanically anchored on the support spacer with a burst pressure of minimum 4 bar(g) making the lifetime of the system expected to exceed 8 years.

Our Vision

Climate change, industrialization and population growth lead to water scarcity across the world. As a consequence, the industrial use of groundwater is restricted or even forbidden in several parts of the world. This stricter regulation makes the re-use of wastewater necessary. Our IPC™ membranes create the possibility of water re-use with reasonable effort.

Our Mission

IPC™ membranes are a key component in wastewater treatment and water reuse. By making IPC™ membranes the preferred membranes for potable water, wastewater and industrial process water treatment, we are reducing the world water footprint and truly contributing to a more sustainable world.